Product Categories

- Marine Cable

- Marine Power Cable

- Marine Communication Cable

- Marine Control Cable

- Offshore Cable

- Crane Cable

- Mining Cable

- Electrical Cable

- Solar Cable

- Underwater Cable

- Wind Cable

Application

This cable is intended for trailer communications systems of port equipment; and high mechanical stress, high frequency alternating bending operation of the control system.

Service Conditions:

1.Cable rated voltage U / U is 0.6 / 1 kV

2.The cables permissible Long-term working temperature is 90℃, it can work under the

lowest temperature -35℃. Minimum bending radius is 6 D of the diameter of the cable, and is abrasion resistance, ozone resistance, oil resistance, flame retardant, ultraviolet radiation and moist resistance characteristics. (D =cable diameter)

3.Insulation layer of cable is the EPR rubber mixtures, the inner and outer sheathing using CR rubber mixtures.

4.The core color of cables is black, white codes with consecutive numbers, sheathing layer of the cable is black.

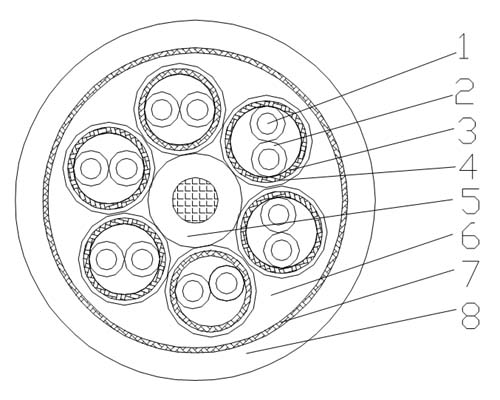

Construction

1.Copper wire Conductor

2.EPR Insulation

3.Braid Screen

4.Defender layer

5.Reinforced Core

6.Inner Sheath

7.Braid reinforced layer

8.CR Outer Sheath

Code Design

| Cable for Port machinery | G |

| Cable for Festoon systems | YD |

| Twisted Pair Shielded | S |

| EPR Insulation | E |

| CR Sheath | F |

| Flexible Conductors | R |

| Aramid fiber reinforced | J |

Specifications

| Nominal cross section mm2 | Construction mm | Nom.OD of cable mm | Max. OD of cable mm | Ref. weight of cable(Kg/km) | Max. load(N) |

| 4×2×0.5 | 4×2×16/0.20 | 23.6 | 26.0 | 560 | 140 |

| 6×2×0.5 | 6×2×16/0.20 | 26.8 | 29.5 | 850 | 160 |

| 4×2×1 | 4×2×32/0.20 | 30.5 | 31.5 | 862 | 150 |

| 6×2×1 | 6×2×32/0.20 | 32.0 | 33.5 | 1200 | 180 |