Product Categories

- Marine Cable

- Marine Power Cable

- Marine Communication Cable

- Marine Control Cable

- Offshore Cable

- Crane Cable

- Mining Cable

- Electrical Cable

- Solar Cable

- Underwater Cable

- Wind Cable

Application

This cable is intended for energy chain with motor system of port equipment. cables are capable of torsion according to type and can be used in high speeds and accelerations. Demands for UV-resistance, flame resistant, halogen free cable and resistance at high or very low temperatures can be met with many control cables.

Performance

1.The rated voltage of cable is 0.6/1KV

2.The cables permissible Long-term working temperature is 100℃, it can work under the

lowest temperature -35℃. Minimum bending radius is 6 D of the diameter of the cable,

and is high abrasion resistance, ozone resistance, oil resistance, flame retardant,

ultraviolet radiation and moist characteristics. (D =cable diameter)

3.Insulation layer of Cable for TPE mixture, outer sheath used PUR mixture.

4.The cores of cables is black, white codes with consecutive numbers, which includes a core

Green / yellow earth core. The cable sheathing layer is black.

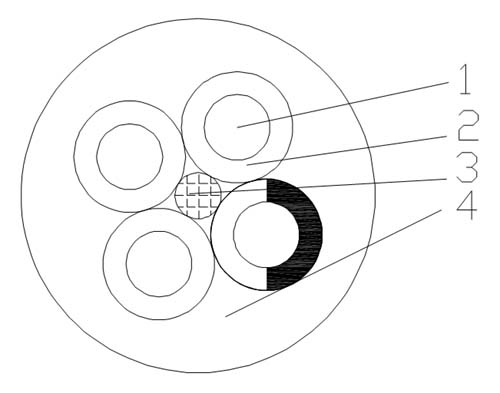

Construction

1.Conductor:Fine Stranded copper wire

2.Insulation:TPEE Compound

3.Nylon Reinforced Core

4.Outer Sheath

Code Design

| Cable for Port machinery | G |

| Reinforced | G |

| For Motor systems | D |

| PUR Sheath | U |

| Flexible Conductors | R |

Specifications

| Cross section(mm2) | Conductor construction ( tinned copper) | Nom. OD of Cable(mm) | Max. OD of Cable(mm) | Approx weight(kg/km) |

| 1×4 | 1×126/0.20 | 6.7 | 7.4 | 79 |

| 1×6 | 1×189/0.20 | 7.6 | 8.3 | 105 |

| 1×10 | 1×322/0.20 | 8.9 | 9.8 | 155 |

| 1×16 | 1×513/0.20 | 10.3 | 11.3 | 222 |

| 1×25 | 1×798/0.20 | 12.1 | 13.3 | 328 |

| 1×35 | 1×1121/0.20 | 13.5 | 14.9 | 435 |

| 1×50 | 1×703/0.30 | 15.7 | 17.3 | 599 |

| 1×70 | 1×999/0.30 | 18.4 | 19.9 | 836 |

| 1×95 | 1×1332/0.30 | 20.2 | 21.8 | 1075 |

| 1×120 | 1×1702/0.30 | 22.0 | 23.8 | 1341 |

| 1×150 | 1×2109/0.30 | 24.4 | 26.4 | 1653 |

| 1×185 | 1×1443/0.40 | 27.0 | 29.2 | 2004 |