Product Categories

- Marine Cable

- Marine Power Cable

- Marine Communication Cable

- Marine Control Cable

- Offshore Cable

- Crane Cable

- Mining Cable

- Electrical Cable

- Solar Cable

- Underwater Cable

- Wind Cable

JIS C3410 ARMORED CONTROL CABLE

JIS C3410 Armored Control Cable

This product is suitable for all kinds of ships and offshore oil platforms and other control structures and electrical transmission .

Voltage rating: 250V

Maximum conductor temperature: 85°C

-JISC 3410-1999

-IEC 60092-350

-IEC 60332-1

-IEC 60332-3 Cat.AF(for FA-type)

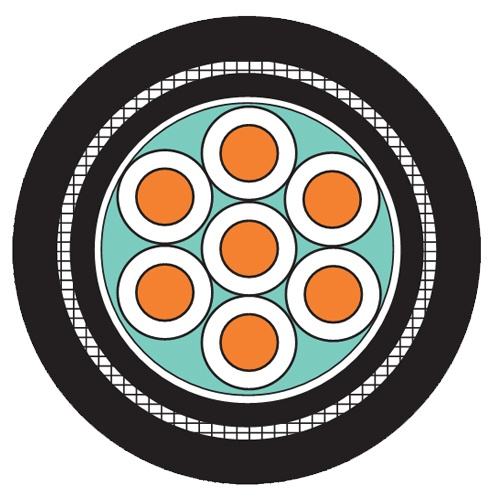

JIS C3410 ARMORED CONTROL CABLE DIAGRAM

| Conductor | M | Tinned annealed stranded copper, class 2 according to IEC 60228 |

| Insulation | P | 85°C EPR as per JIS C 3401 |

| Cabling | Insulated conductors shall be cabled. Flame retardant & non-hygroscopic fillers may be used |

|

| Bedding | Y | PVC as per JIS C 3401 |

| Armor | C | Galvanized steel wire braid |

| Sheath | Y | PVC as per JIS C 3401 |

| Core identification | Black No. on white insulation /Black No. on white insulation, G/Y | |

| Outer sheath color | Black |

Installations recommendations

Minimum cable bending radius

The internal radius of cable bends which are not subjected to movements by expansion, is not to be less than :

6 times the external diameter of cable

Cable which are subjected to movements by expansion and the high voltage cable are to be bent to a form of at least 12 times cable diameter.

Installations temperature

Minimum recommended temperature of installations :

-10°C Ship wiring cable with PVC sheath

-20°C Elastomeric on/off shore cables

Installations pulling force

The cable pulling force can be estimated, as a maximum limit :5Kp per mm2 conductor area in the cable.Additional tension will be supplied from the braid and the insulation

and sheathing compound.

250V (FA-) MPY

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

(FA-) MPY | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

|||

| mm² | No./mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 8.7 | 0.4 | 85 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 9.9 | 0.4 | 125 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 11.9 | 0.5 | 190 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 15.5 | 0.7 | 315 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 18.3 | 0.8 | 465 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 22.1 | 0.9 | 665 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 24.8 | 1 | 870 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 28 | 1.2 | 1160 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 35.9 | 1.5 | 1790 |

250V (FA-) MPYC

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

(FA-) MPYC | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 10 | 0.4 | 155 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 11.2 | 0.4 | 205 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 0.3 | 13.2 | 0.5 | 290 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 0.3 | 16.8 | 0.7 | 445 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 0.3 | 19.6 | 0.8 | 615 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 0.3 | 23.4 | 0.9 | 840 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 0.3 | 26.1 | 1 | 1070 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 0.3 | 29.3 | 1.2 | 1290 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 0.4 | 37.7 | 1.5 | 2180 |

250V (FA-) MPYCY

| No. of cores |

Conductor | Thick. of insulation |

Thick. of bedding |

Dia. of steel wire |

Thick. of covering |

(FA-) MPYCY | ||||

| Size | Construction | O.D | Nom. overall dia |

Tolerance | Cable Weight |

|||||

| mm² | No./mm | mm | mm | mm | mm | mm | mm | mm | kg/km | |

| 2 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 0.9 | 12 | 0.5 | 205 |

| 4 | 1 | 7/0.43 | 1.29 | 0.7 | 1.1 | 0.3 | 0.9 | 13.2 | 0.5 | 260 |

| 7 | 1 | 7/0.43 | 1.29 | 0.7 | 1.2 | 0.3 | 0.9 | 15.2 | 0.6 | 350 |

| 12 | 1 | 7/0.43 | 1.29 | 0.7 | 1.3 | 0.3 | 1 | 19 | 0.8 | 530 |

| 19 | 1 | 7/0.43 | 1.29 | 0.7 | 1.4 | 0.3 | 1.1 | 22 | 0.9 | 720 |

| 27 | 1 | 7/0.43 | 1.29 | 0.7 | 1.6 | 0.3 | 1.2 | 26 | 1 | 980 |

| 37 | 1 | 7/0.43 | 1.29 | 0.7 | 1.7 | 0.3 | 1.3 | 28.9 | 1.2 | 1240 |

| 44 | 1 | 7/0.43 | 1.29 | 0.7 | 1.8 | 0.3 | 1.3 | 32.1 | 1.3 | 1470 |

| 77 | 1 | 7/0.43 | 1.29 | 0.7 | 2.1 | 0.4 | 1.5 | 41.1 | 1.6 | 2470 |