Product Categories

- Marine Cable

- Marine Power Cable

- Marine Communication Cable

- Marine Control Cable

- Offshore Cable

- Crane Cable

- Mining Cable

- Electrical Cable

- Solar Cable

- Underwater Cable

- Wind Cable

Applications

For connection of mobile machines with very high mechanical load, especially in mines, e.g. for coal cutting machines. Suited in particular for extreme bending stressing with low tensile stress.The cable meets requirements given in test standards DIN VDE 0472, Part 818 “ behaviour under clamping stress”. It secures that a damage produced by clamping is detected as an earth fault with maximum possible probability.

For the connection of mobile machines under extremely high mechanical loads, mainly in mining situations, e.g. for coal-cutting machines, free trailing applications, particularly suitable for extreme bending loads, high tensile stress and impact and crushing loads. The torsion and tensile-stress-resistant armour, in conjunction with the high flexibility of the cable, also allows the cable to be operated via guide pulleys or used as a reeling cable on Load-Haul-Dumpers (LHDs). The phase-concentric monitoring shield and the common-concentric earth conductor, in conjunction with appropriate monitoring equipment, make it possible to monitor the cable for insulation faults and damage resulting from external influences. The cable can be supplied with 2, 3 or 6 pilot cores.

Construction

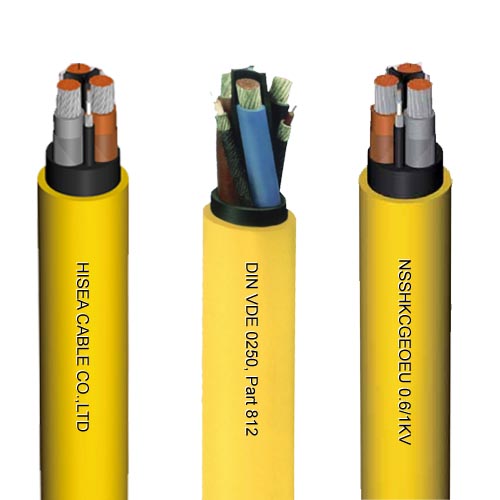

Standards : VDE 0250 Part 812

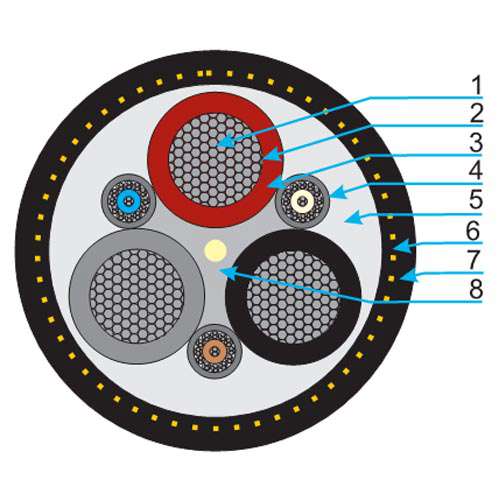

Conductor (1) :Tinned copper, extra fine stranded (class 5) according to DIN VDE 0295

Separator (2) : Polyester tape

Insulation (3) : Rubber, compound type 3GI3 acc. to DIN VDE 0207 part 20

Special pilot/earth core element (4) : Copper and steel conductor capable of expansion and compression covered with EPR insulation. Earth core as a spiral of tinned copper bunches covered with semi conductive tape

Inner sheath (5) : Semi conductive inner sheath

Reinforcement (6) : Steel wire braid

Outer sheath (7) : Outer sheath of black chlorinated rubber compound 5GM5, abrasion and tear-resistant, oil-resistant and flame retardant

Core arrangement (8) : Cores lay up around semi conductive cradle with centre Kevlar rope

Technical data

| Nominal voltage U0/U | 0.6/1 kV |

| Permissible surface temperature | fixed installation: -40°C to +80°C moved: -25°C to +80°C |

| Max. conductor temperature | in service: + 90°C in case of short circuit: + 200°C |

| Bending radius | moved min.: 3 X D* fixed min.: 2 X D* in guide pulleys and on drums 4.5XD* *D | cable diameter |

| Core colours | brown, black, grey |

| Sheath colours | black, other colours available |