Product Categories

- Marine Cable

- Marine Power Cable

- Marine Communication Cable

- Marine Control Cable

- Offshore Cable

- Crane Cable

- Mining Cable

- Electrical Cable

- Solar Cable

- Underwater Cable

- Wind Cable

Application

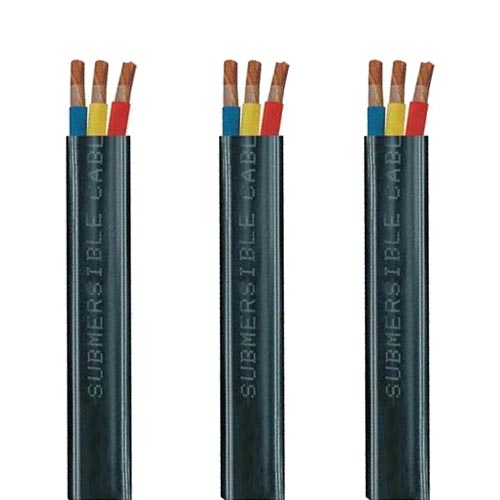

Under Water Cable is intended for power feeder and/or communication/control applications under water.It can be divided into waterproof cable for submersible pumps and submarine cables.Submersible cable is suitable for power connection of submersible motor of AC 50Hz, voltage 300/500V and below (one end of cable is in the water, the other is in the air)

Constructions

Conductor:Bare copper wire IEC 60228 Class 5/DIN VDE 0295 Class5

Insulation:Waterproof Rubber

Filler:Waterproof Rubber

Sheath:Waterproof Rubber.

Submersible Flexible Cable Specification

| Core | Nominal sectional area of main conductor mm2 | |

| Main core | Earthing core | |

| 1.3 | 0 | 4、6、10、16、25、35、50、70 |

| 3 | 1 | |

| Nominal section mm2 | 1-core | 3-cores | DC resistance of main conductor at 20℃ (Ohms.km)≤ |

||

| Max. overall diameter mm |

Calculated mass kg/km |

Max. overall diameter mm |

Calculated mass kg/km |

||

| 4 | 9.0 | 100 | 17.0 | 361 | 4.950 |

| 6 | 9.5 | 126 | 19.0 | 463 | 3.300 |

| 10 | 12.5 | 220 | 24.0 | 762 | 1.910 |

| 16 | 13.5 | 282 | 26.0 | 972 | 1.210 |

| 25 | 16.5 | 432 | 32.0 | 1509 | 0.780 |

| 35 | 18.5 | 564 | 36.0 | 1988 | 0.554 |

| 50 | 5 | 794 | 43.0 | 2836 | 0.386 |

| 70 | 23.5 | 1045 | 47.5 | 3701 | 0.272 |

| Cores×Nominal section mm2 |

3+1 cores | DC resistance of main conductor at 20℃ (W.km)≤ |

|

| Max.overall diameter mm |

Calculated mass kg/km |

||

| 3×4+1×2.5 | 18.0 | 412 | 4.950 |

| 3×6+1×4 | 20.0 | 536 | 3.300 |

| 3×10+1×6 | 25.0 | 853 | 1.910 |

| 3×16+1×6 | 27.0 | 1054 | 1.210 |

| 3×25+1×10 | 33.0 | 1666 | 0.780 |

| 3×35+1×16 | 36.5 | 2112 | 0.554 |

| 3×50+1×16 | 43.5 | 2987 | 0.386 |

| 3×70+1×25 | 48.5 | 3961 | 0.272 |

Note: The finished cable should withstand the transverse sealing hydraulic test of water pressure up to 3040Pa for 2h.